How To Build Lego Ninjago Sets

How to brand your own LEGO set up

Posted by ,

This article has been written by Kyle, owner and operator of KO Custom Minifigs:

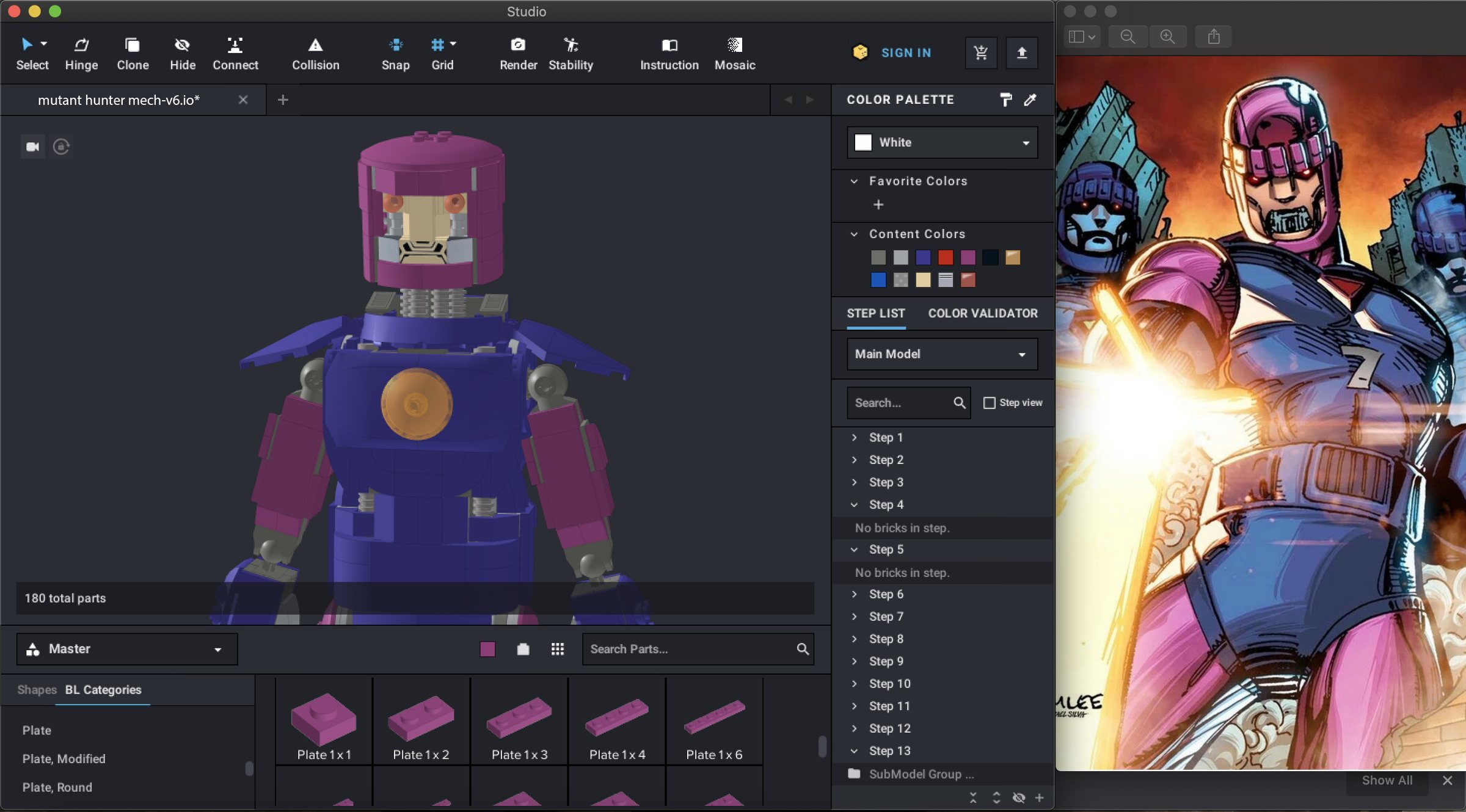

We recently took on a project to make what nosotros have chosen our Mutant Hunter Mech building ready. We are known for making custom LEGO minifigures, just this is the first time that we have ever made a professional quality, custom edifice set.

The process was a lot of fun and I'd like to explain how I did it and what I've learned along the way.

It all starts with an thought - One time y'all have an idea for a LEGO set that you'd like to blueprint, gather images of your subject area matter from all different angles. If the subject is something that appears differently across various forms of media, decide if y'all will be making one verbal wait, or if yours volition be a mash-up of different iterations.

.jpg)

I am not an engineer, but I accept been building with LEGO all of my life. Having said that, the LEGO models that come up out nowadays are some of the most structurally audio models they have e'er fabricated. Long gone are the days of building a Star Wars ship that collapses in one-half while playing with it.

For this reason, I decided to look at recent LEGO Mech Robots when I began the initial phases of designing the MHM. Examining similar builds by LEGO's Master Builders is a bang-up way to ensure that you have a good understanding of the mechanics required to build your model.This is not to say that yous should copy existing designs - your model should all the same be your own work.

Examining LEGO sets that have a similar form to your future model will show you lot where to balance the weight or connection points. You tin practice this by looking at the instruction transmission of a model via a gratis online PDF. Once you have looked at a lot of these, consider ownership the set that is the most useful to your needs and build it so you can encounter how the model is stabilised in person.

Information technology is likewise a expert idea to accept a sense of calibration in mind for how big or modest to make your model. You wouldn't want to jump into things and realise it is non set up to minifigure calibration or that it is way too large. Planning this at present will salvage y'all time afterward. For the MHM, I wanted the build to be adequately big, and have it be a very big size compared to a standard LEGO Minifigure. I decided to become with information technology existence simply most 12 inches tall, which allowed me to plan out how long each arm and leg should be.

Knowing this, I could then expect about how long each sub function of the leg should be. This is important because it determines how many parts can fit inside the space and how you have to adapt them for stability and details.

If you're building something that relies on very specific colours, yous should familiarise yourself with what parts are bachelor in those colours. You can look into this on the colour tab on Bricklink.com, or hither on Brickset.com, as well every bit on the software Bricklink Studio. For MHM, the biggest challenge of the entire process, from designing and edifice, to sourcing parts, etc., was that a large corporeality of the parts used were magenta and dark purple. These colours aren't available for many elements, then it greatly limited the choice of parts to build with.

What features do y'all desire your model to have? Earlier I started designing MHM, I knew that I wanted to have a way for the eyes to light upward, and I wanted to make it as poseable equally I mayhap could, like a giant action figure. Ideally, I wanted to have the translucent orange dish piece on the breast of the MHM light upwards besides, but it wasn't able to be done. Even so, my core features of light-upward eyes and poseability were successful.

During the building procedure I realised I could include an boosted feature, a connectedness point within the MHM's hands that could be used to attach accessories. That's when I decided to include the "tentacle" coil zipper as office of the set up, but the connection point could be used for other interesting attachments similar a brick built energy beam set on, or equally a way to adhere a minifigure. You might encounter like opportunities along your edifice process that allow y'all to add cool, unexpected features.

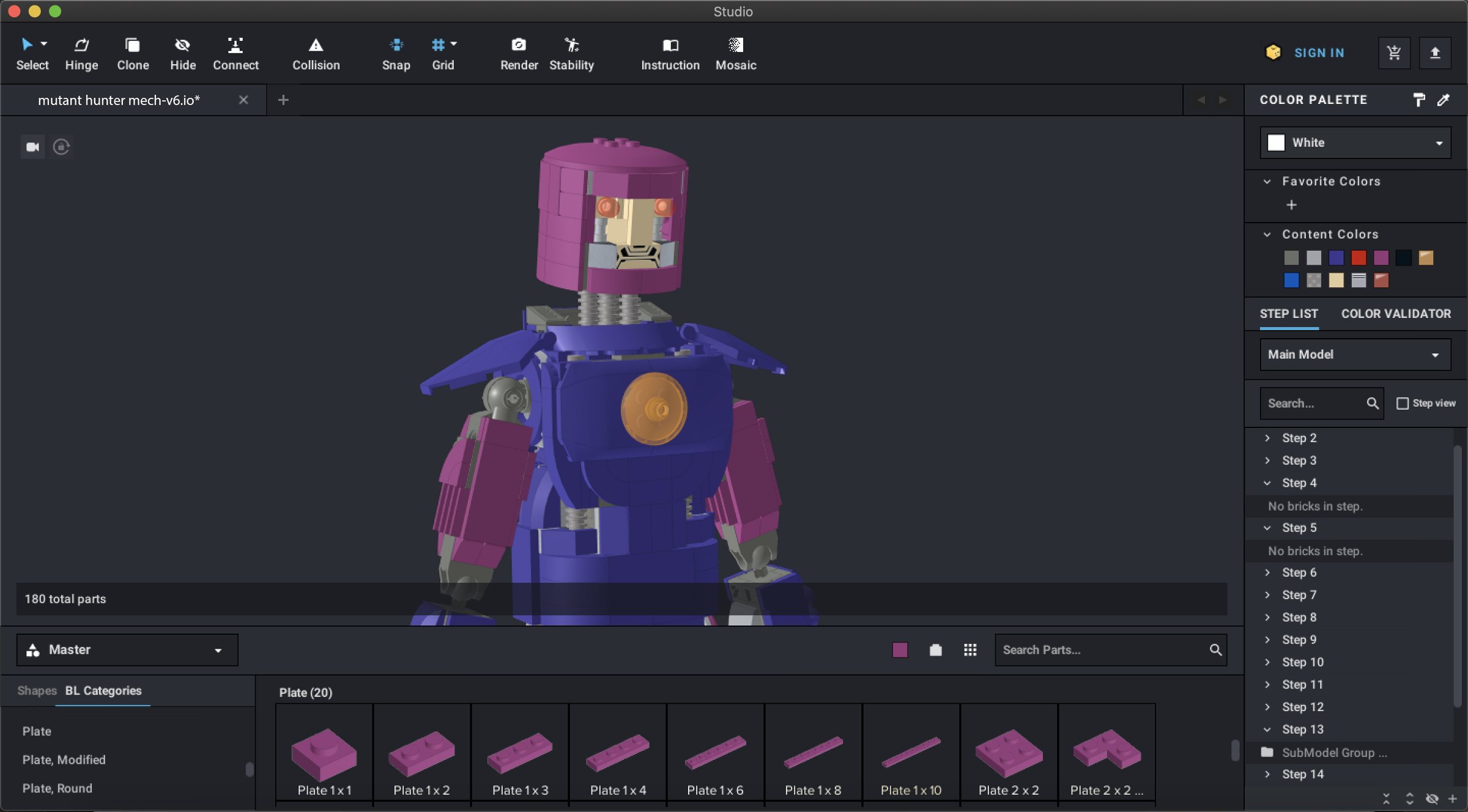

I would highly recommend using the software Bricklink Studio to build your own model. At that place are other digital building programs out in that location, but this is, in my opinion, the best pick. Bricklink Studio allows you to export an inventory list of the parts used in your build so that you lot can upload this list to your Bricklink account. Then you can buy these parts from Bricklink.com using this list.

If you are not familiar with Bricklink Studio or you lot haven't used it much, you may want to watch some YouTube tutorials for it. There are and so many dandy features included in this programme.

Using Bricklink Studio, begin by building something that looks accurate to your reference images. Do this one stride at a fourth dimension. For me I started by edifice the feet, and and then the legs of the MHM. I treated each as a dedicated model within a model, sculpting them to look as accurate as I could go them. LEGO is known for its small details so try to apply that philosophy into your design. You don't want to blitz through the building procedure.

Continue structural strength in mind as you build on screen. Somewhen you will need to test this design with real parts to ensure stability. Digital building allows you lot to explore ideas, and experiment while saving time and money. Alternatively, if you tried to physically build out every choice it would accept significantly longer and would be far more expensive. Along the manner, you volition well-nigh likely end upwards going back and modifying designs that you thought y'all had finished.

I establish that while designing MHM, I would be fairly happy with how something looked, just after reevaluating the entire model, I would become back and change something. It'due south a fluid process, but information technology's important to be open to making these kinds of changes forth the fashion. You don't desire to lock yourself into any designs until you feel the entire model looks as it should.

Try to condense your model where you can. An obvious example of this would exist, instead of stacking three plates on elevation of each other, meet if you tin can use a brick. Most cases this will work, unless the brick in question does non be in the colour yous need but plates exercise.

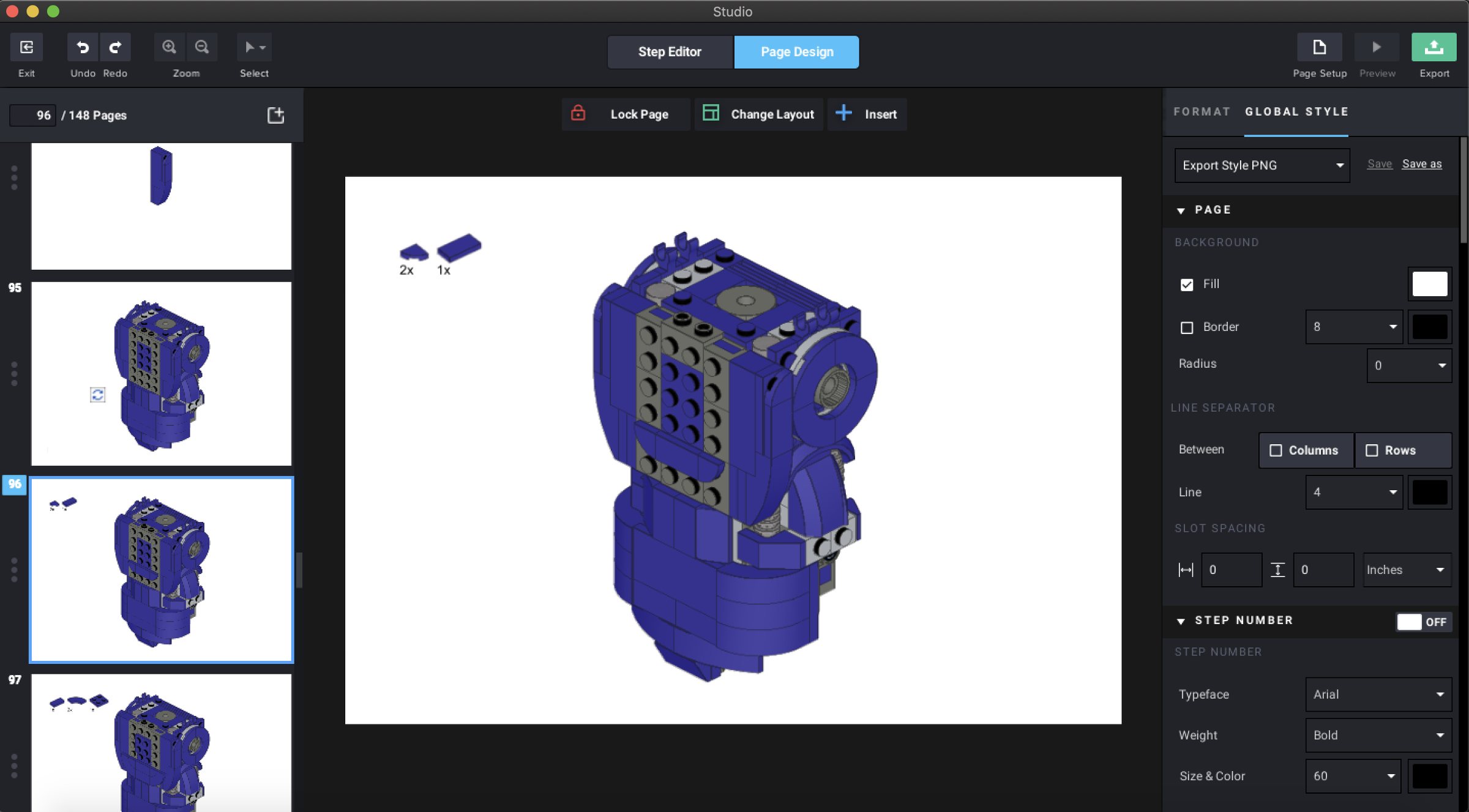

Bricklink Studio has a very well-made instruction generator, although it has a bit of a learning bend to it. I had never used the software to make instructions until at present. The primary difference is that yous need to marking new steps as you are building. The style that I made MHM was that I designed the entire model first, and once it was finished, I physically built the model with existent parts. I so began the process of partially deconstructing small sections at a time.

From these physically deconstructed sections, I would rebuild these areas by hand, as well equally, simultaneously building them in Bricklink Studio. In Bricklink Studio, I would generate a new step after adding almost 5-6 parts into the onscreen build. Making instructions can feel very tedious, but you wouldn't want all of your hard work to be lost now past making confusing steps that the builder cannot follow.

Take this on one area at a time and in several sessions. Once you've got your steps seemingly making sense, print them out and accept a family member or a friend effort to build your model. Note any surface area that confuses them or isn't clear. You may demand to modify the angle showing the building step or change the order of the parts being added.

Yous tin can use Bricklink Studio'south instruction maker to not but organise your building steps but also blueprint the terminal expect of your pages. I'thousand not extremely familiar with this side of their editor merely there are several videos online that go over the settings to change the look and layout of the folio. I went a different route for my MHM set. Depending on your level of experience with graphic pattern I would caution you lot to stick with Bricklink Studio's teaching maker.

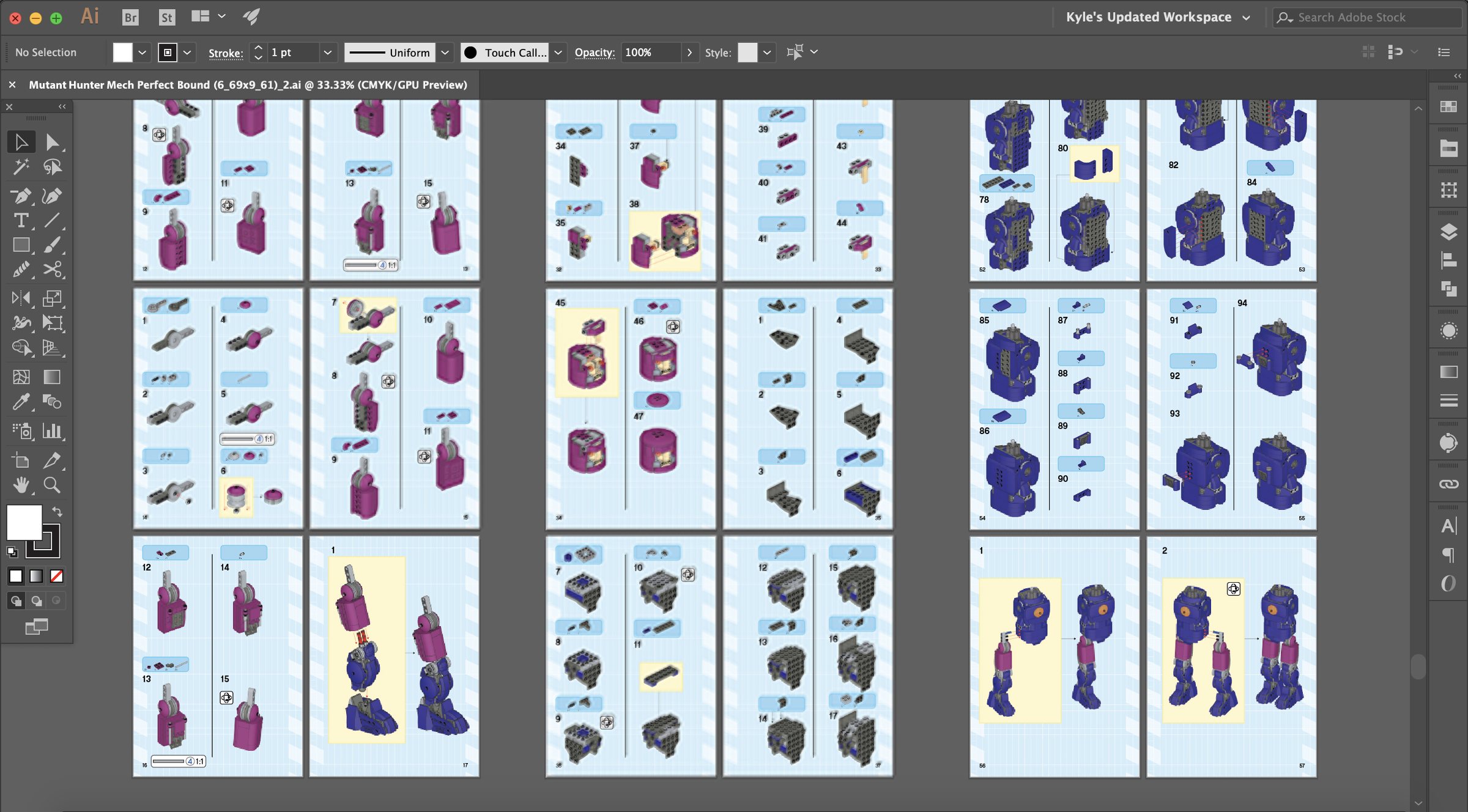

I wanted to make a printed instruction booklet, and so I was only using Bricklink Studio'due south instruction maker to generate the images I would need of each edifice step. In one case I had the high resolution PNG images exported from Bricklink Studio, I then used Adobe Illustrator to pattern my actual pages.

I was using a specifically sized template which included bleeds and safety areas. I downloaded the template from the printing company I was ordering from. If y'all go the road of making your own printed booklets, it is expensive and fourth dimension-consuming. Exist sure that the images you're using are loftier resolution, and that the scale of parts is consistent throughout the booklet.

I had a percentage calculated out that I would scale each epitome downward to. Don't overload a unmarried page with too many steps. Test that your pages are readable by printing out a page at home, at actual size. If you only require digital edifice instructions, y'all tin export the instructions y'all've made in Bricklink Studio as a PDF file. Some custom models offer their instructions as a digital download or come on a USB drive.

You will desire to have high quality images of your model to show the globe. I would recommend taking high resolution photos of your finished model, against a plain white background, or yous could make a loftier resolution, digitally rendered paradigm of your model using the return feature within Bricklink Studio. For either arroyo, a static pose of your model is a good start, followed by other images that showcase its special features.

If you lot would like to get fifty-fifty further, and have a box printed for your custom gear up, I would caution you lot in a like way nigh the costs and level of graphic design experience before taking information technology on. Nevertheless, for MHM I found a box printing company online, and worked within a dieline template they provided. The dieline template corresponded to the specific box shape and dimensions I was ordering.

To effigy out what box size I needed, I measured and trimmed a paper-thin shipping box at home. The dimensions factored in that the box had to contain the printed educational activity booklet, and the parts for the prepare (which were separated into 5 bags for each stage of the build). I ensured this was authentic by physically testing that all components would fit. In terms of product, I also had samples of the box and the instructions printed up. This was to ensure that the color levels were where I wanted them.

Printing in CMYK oftentimes makes your artwork announced darker, or more blue. If you are designing your own box/ instructions, bank check that your document's color profile is set correctly to RGB (screen) or CMYK (print). Also, check for any other specific directions that the company you are using has for formatting your files or other settings. This can often exist plant on the company'due south FAQ section or by asking the company.

If you lot want to offering the full set, parts included in the box and ready to build, you will need to source every office. I mainly have used Bricklink to source the parts needed for each set. I have also used LEGO's Bricks and Pieces service, but the availability of parts is ofttimes hit or miss.

The matter that I would stress the most is, if you lot plan to provide the parts, before you finalise your model, brainstorm printing X corporeality of copies of instructions, boxes, etc., double check that all of the parts you lot are using are readily available to fulfil all of your sets. Certain parts might appear to exist available to purchase, only upon looking further but a handful of sellers might take them. This is more ofttimes the case for parts that have only ever appeared in 1 fix, at depression quantities in that set up.

Again, this was more of a factor for MHM, due to the unusual colour palette I was working in for magenta and night purple elements. Once you have your set finalized, and are not using any elements that you lot cannot buy, you can continue with the rest of the procedure. To order all of the parts I made multiple wanted lists on Bricklink. I list is the master list of the original build, and other lists were bulk ordering lists that had the quantity of each office multiplied by 10. Using Bricklink'south smart buy feature, and wanted list ownership features, you can social club parts and utilize the order to your list to track your inventory quantities and see what is still needed.

Finally, in one case you accept the parts for your set you volition demand to sort them all out. I did this by sorting the parts into a few of the Akro-Mills sorting drawer bins. Each bin is labelled with what it contains. They are a dandy mode to keep things bully and organised. To sort each purse, I take a listing of the parts and quantity required, and I scan through the rows and columns of the Akro-Mills sorting drawers, gathering what is needed.

Once I have all the parts, I double-check the lot of gathered pieces and advisedly slide the tray of parts into a plastic bag, which is so sealed with a oestrus sealer, and numbered with a sticker. In one case the parts are bagged, they are then packed into one of our custom boxes, along with a printed instruction booklet, (which has been sealed in plastic wrap) and the set is prepare to exist sent out.

1 affair's for certain: creating your own LEGO set is a lot of piece of work, but a labour of love!

If you'd like to buy your own Mutant Hunter Mech, you lot exercise and so at KO Custom Minifigs for $225.

98 likes

Source: https://brickset.com/article/66046/how-to-make-your-own-lego-set

0 Response to "How To Build Lego Ninjago Sets"

Post a Comment